REPURPOSING THE INDUSTRIAL WASTE IN TERRAIN

In this project, we used unwanted industrial waste found in Terrain, a modern Australian architecture site in Fitzroy. The aim was to experiment with how broken bricks could be reused with mycelium instead of being discarded. Construction waste such as bricks normally ends up in landfill, where it takes up space, contributes to pollution, and requires large amounts of energy to manage. By combining the brick fragments with mycelium, the material was able to bond together and form a new structural mass.

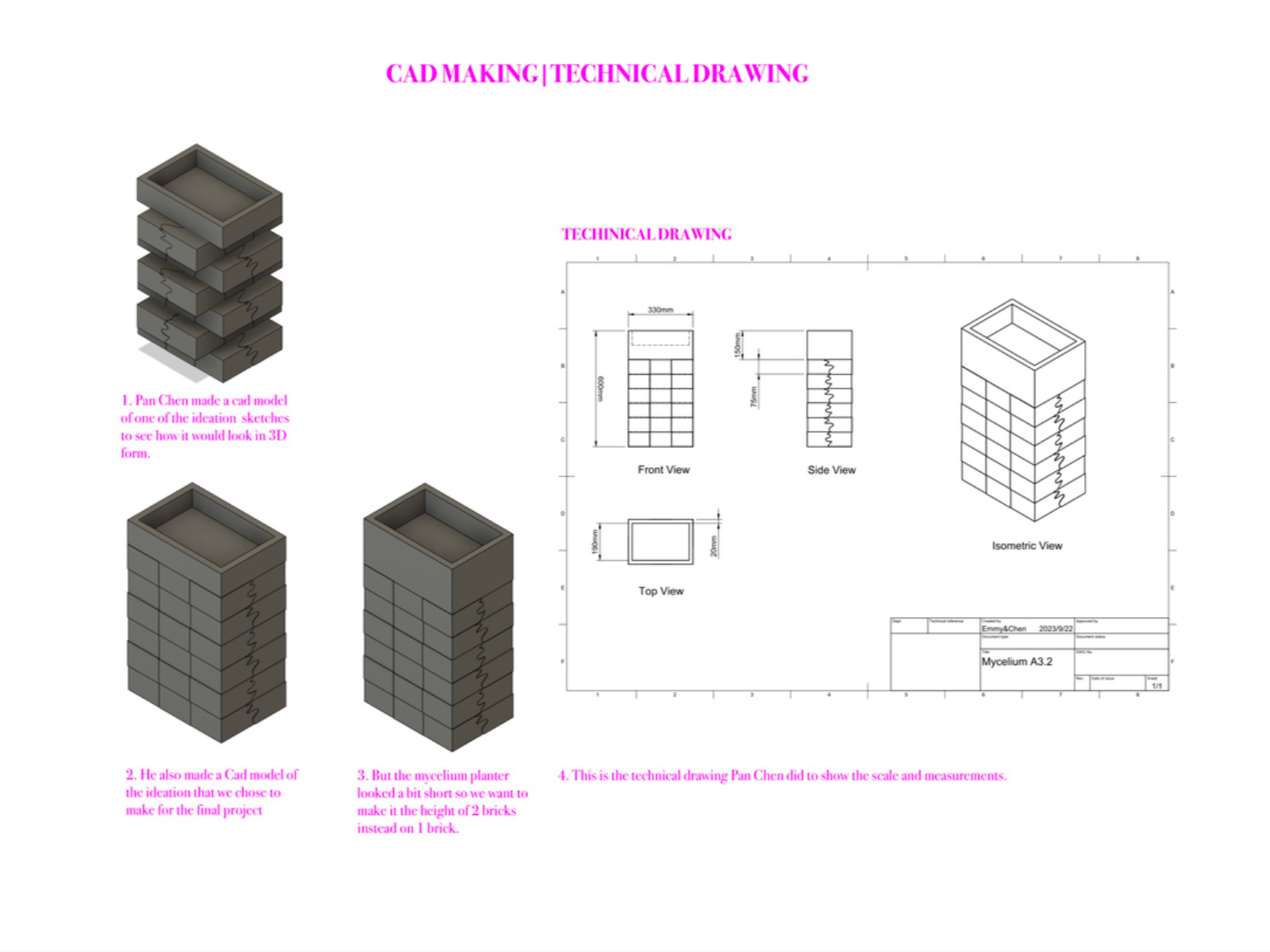

We also wanted to create something specifically for Terrain’s future use, as the building is being transformed into a bookshop. For this reason, we designed a planter made from the reclaimed bricks and mycelium mixture. This planter gives the waste a second life, turning discarded materials from the site into a functional and sustainable object that can remain within the space.

EXPERIMENTING

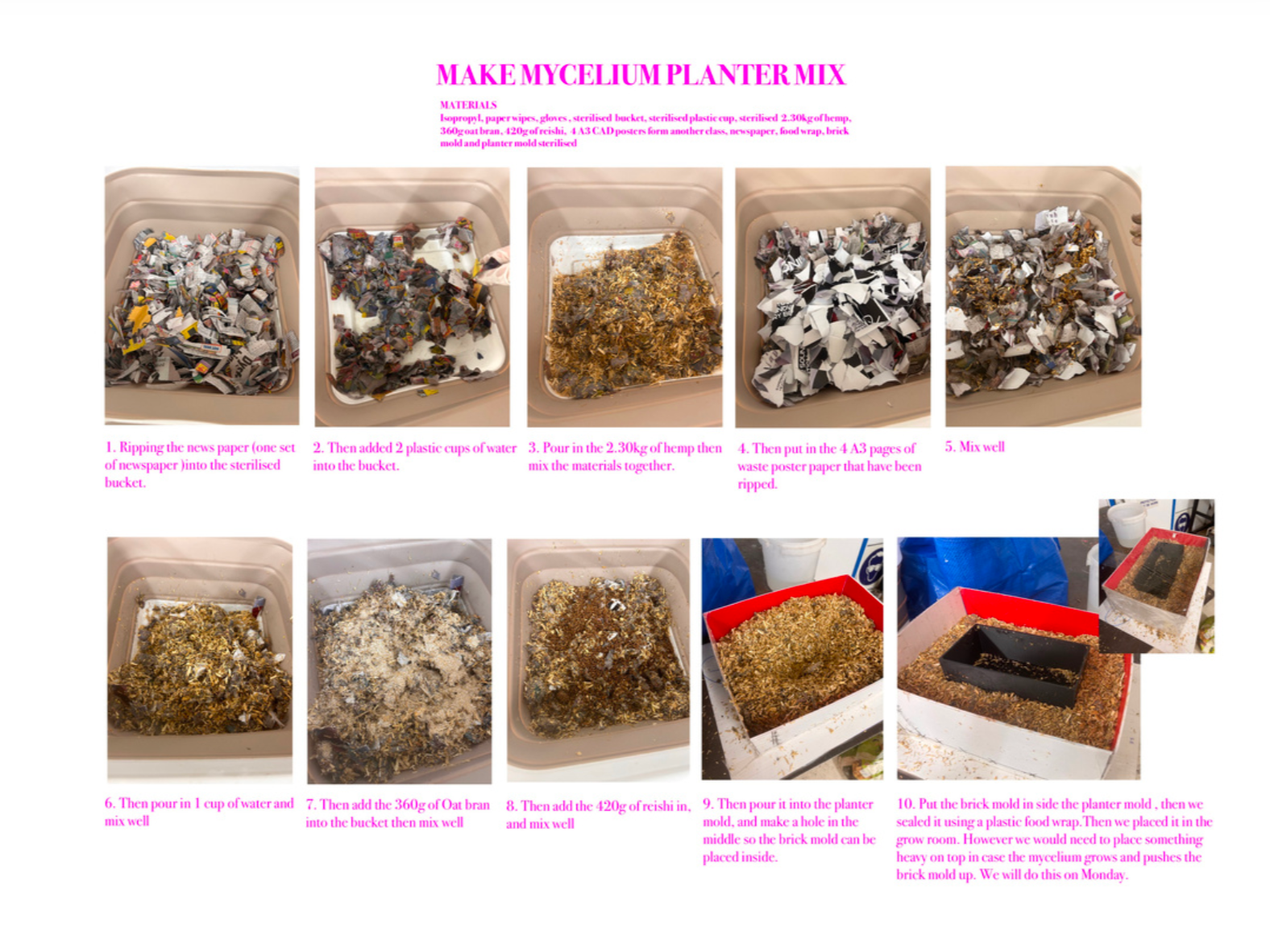

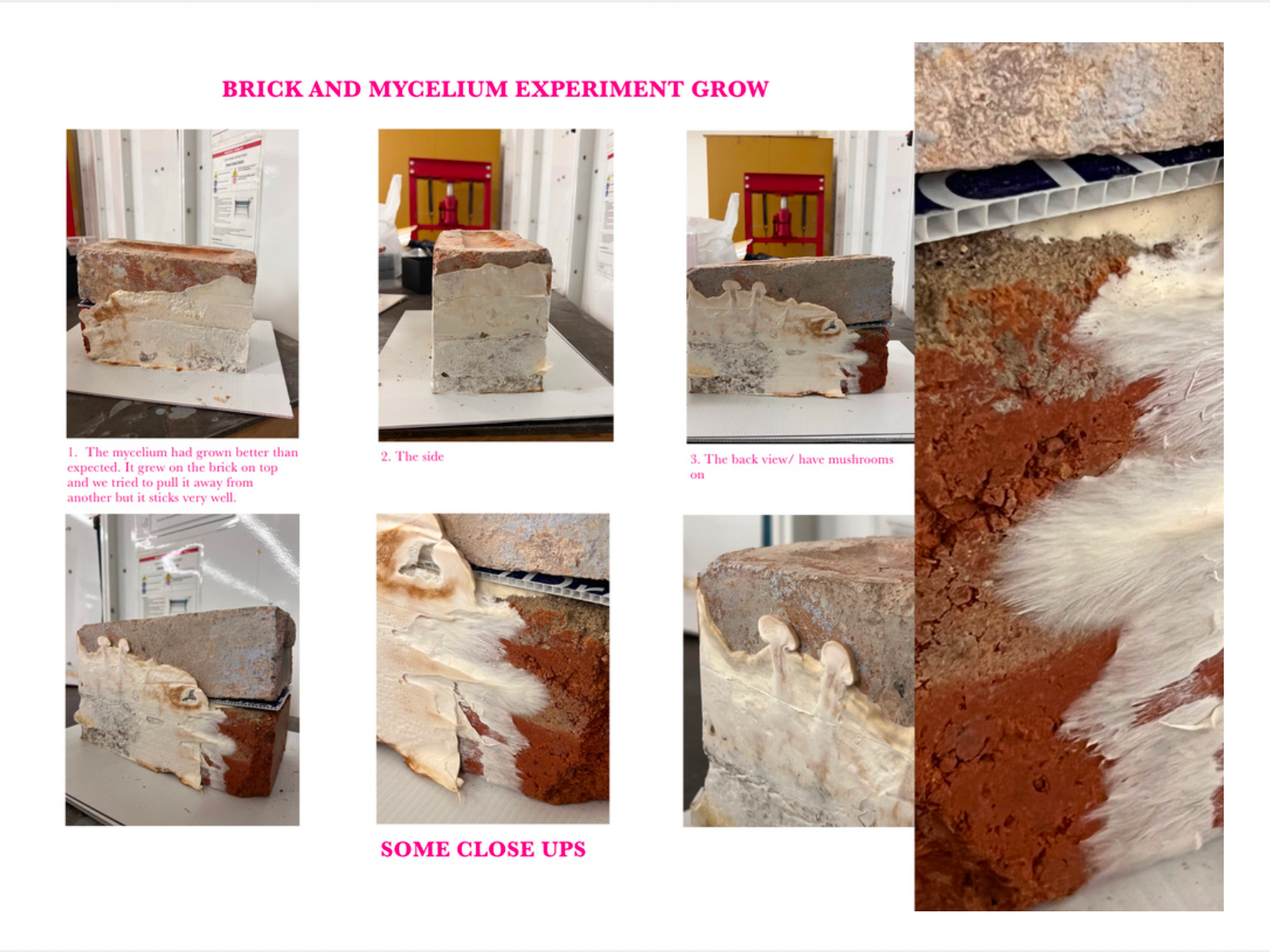

We began by collecting unwanted broken bricks from Terrain and bringing them into the workshop to experiment with moulding the bricks and mycelium into a new brick form. The bricks were cleaned with alcohol and fully dried to ensure no moisture remained, since water can negatively affect mycelium growth.

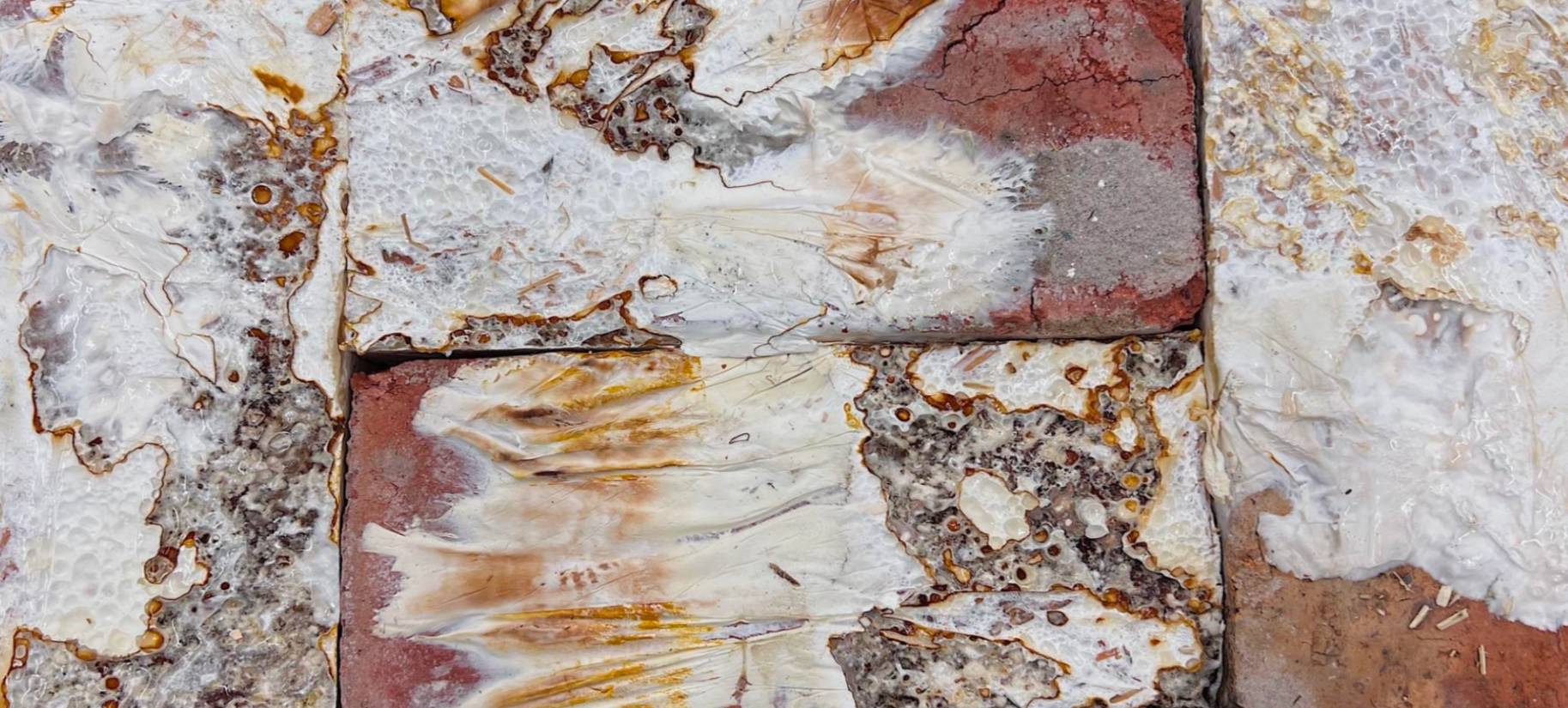

After dehydration, we placed the brick fragments into a mould and poured the mycelium mixture over them, creating a half-brick, half-mycelium structure.

The bottom photos show the growth progress. On the left, the first two weeks of growth were soft and still developing. After dehydrating the sample, the final result (shown on the right) became thinner, stronger, and more compact. It held its shape without crumbling or loose particles, which showed that the process was structurally stable and had potential for further development.

After discovering that the mixture of brick and mycelium worked successfully, we developed it into a planter. This was a very fun project because we were able to take something that was considered waste and transform it back into a useful object.

The process did not require heavy machinery, high temperatures, or large amounts of electricity, which makes it far more sustainable than producing a new brick or ceramic planter. It shows that discarded materials can be reintroduced into everyday life in a low-energy, environmentally friendly way.

MYCELIUM BRICK PLANTER

Some questions you may have

-

1 cup of water

300g of sterilised hemp

60g of oat bran

70g of reishi

Newspaper

-

The bricks were first dried individually, then placed together in a mould with space left for the mycelium to grow and merge the pieces.

After 14 days in a humid environment, the mycelium successfully grew through the cracks and bonded the fragments, forming a single larger brick.